Introduction:

Needle positioners are crucial for precision in industrial and home sewing machines, ensuring the needle stops exactly where it should. However, many users notice a persistent noise at low speeds, which can be both annoying and concerning. Is this noise normal, or does it signal a potential issue? In this article, we’ll explore why needle positioners make noise, how to differentiate between harmless and problematic sounds, and what steps you can take to troubleshoot and prevent noise issues. Let’s find out how to keep your sewing machine running smoothly and quietly.

What is a Needle Positioner and How Does It Work?

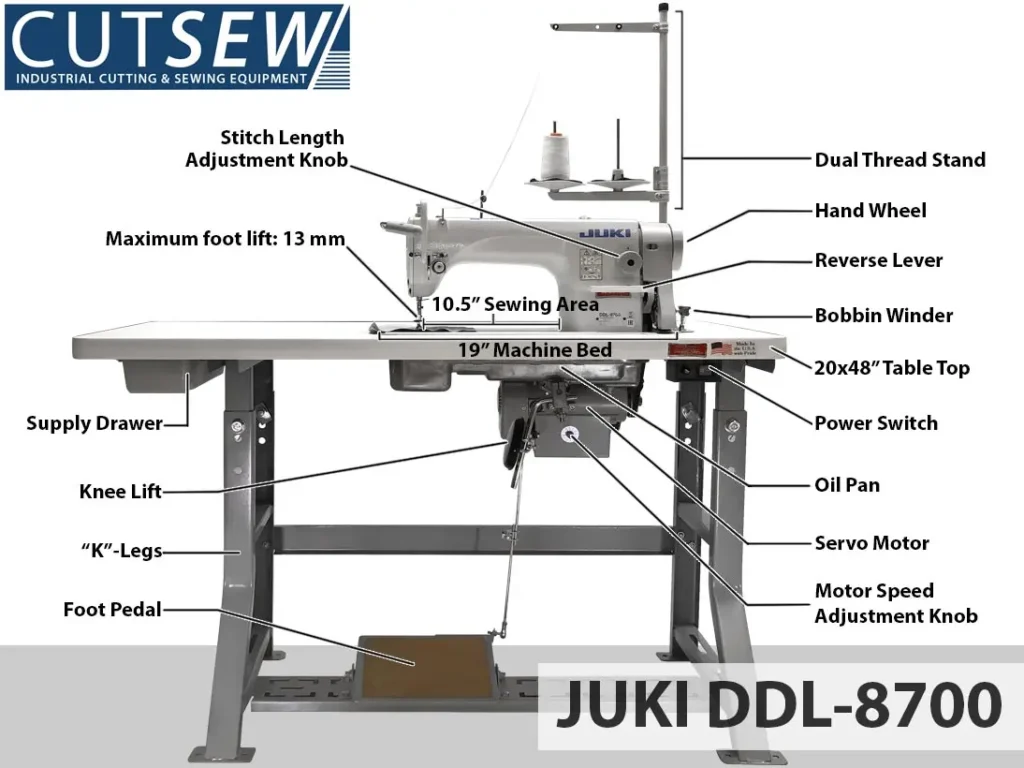

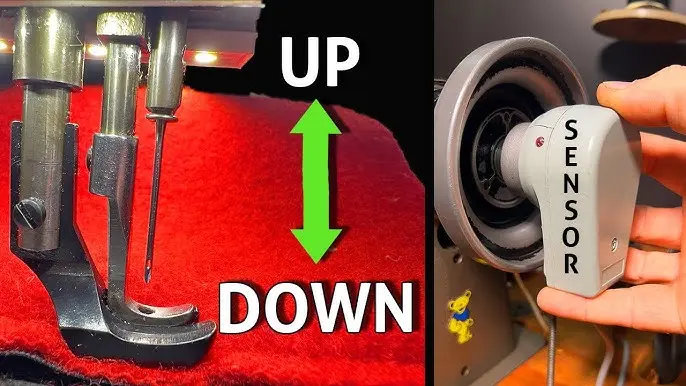

A needle positioner is a device used in sewing machines to control the stopping position of the needle automatically. It ensures the needle halts either in the up or down position, improving accuracy and efficiency, especially in industrial settings. The positioner works alongside the motor, using sensors to detect the needle’s movement and signal the motor when to stop. This feature is essential for precision stitching, reducing manual adjustments, and enhancing workflow in both manual and automated sewing tasks.

Common Causes of Noise in Needle Positioners at Low Speeds

Many users report hearing unusual noises when the needle positioner operates at low speeds. This can be alarming, but it’s often due to a few common reasons:

- Motor Operation: At lower speeds, the motor may produce a humming or buzzing sound as it struggles to maintain consistent torque.

- Part Movement and Vibration: The internal components of the positioner, such as gears and sensors, can vibrate more noticeably at slower speeds.

- Age and Wear: Older needle positioners may become noisier due to worn parts, misalignment, or a lack of proper lubrication.

Understanding these factors can help you identify whether the noise is a normal operational sound or an indication of a problem.

Normal vs. Problematic Noises: What to Listen For

Knowing the difference between normal and problematic noises can save you from unnecessary repairs and downtime. Here’s what to listen for:

Normal Sounds:

- Soft Humming: This is typically the sound of the motor running, especially when adjusting the needle position.

- Light Clicking: Clicking can occur when the needle changes direction or when sensors engage to stop the needle.

Problematic Sounds:

- Loud Grinding: This could indicate worn gears or a lack of lubrication.

- High-Pitched Whining: A whining sound often points to motor issues or an overloaded positioner.

- Irregular Thumping: Thumping noises may be a sign of loose parts or a misaligned needle.

If you notice any of the problematic sounds, it’s best to troubleshoot the issue to prevent further damage.

Factors Influencing Noise Levels in Needle Positioners

Several factors can affect the noise levels in needle positioners, making them louder or quieter depending on their quality and maintenance:

- Motor Quality and Age: High-quality, newer motors tend to run quieter. Older motors, however, may have worn components that produce more noise.

- Type of Needle Positioner: Different types of needle positioners (e.g., mechanical vs. electronic) can produce varying levels of noise, with electronic models generally being quieter.

- Lubrication and Maintenance: Regular lubrication reduces friction between moving parts, significantly lowering noise levels. Poor maintenance can cause components to wear out faster, resulting in louder operation.

Troubleshooting Guide: Reducing Noise at Low Speeds

If your needle positioner is making excessive noise at low speeds, follow these steps to diagnose and resolve the issue:

Step 1: Inspect for Loose Parts

Check for any screws or components that might have loosened over time. Tighten them carefully to eliminate rattling noises.

Step 2: Lubricate Moving Parts

Apply a sewing machine-safe lubricant to the needle bar, gears, and motor. This can reduce grinding and squeaking noises caused by friction.

Step 3: Check for Motor Wear

Examine the motor for signs of wear, such as excessive heat or unusual smells. If the motor seems worn out, consider replacing it or consulting a professional.

Step 4: Adjust the Speed

Try slightly increasing the speed of the machine. Some positioners perform better and quieter at moderate speeds rather than very low speeds.

Preventative Measures for Quieter Operation

Maintaining your needle positioner properly can prevent noise issues from developing. Here are some effective preventative measures:

- Routine Lubrication: Keep all moving parts well-lubricated to minimize friction and wear.

- Regular Inspection: Check for loose parts, alignment issues, and signs of wear every few months.

- Use Quality Parts: Invest in high-quality, compatible parts for replacements to ensure smoother operation.

- Maintain a Clean Workspace: Dust and debris can get into the machine’s components, causing noise and damage. Keep your sewing area clean and free of lint.

How to Determine if the Noise Indicates a Problem

While some noise is normal, there are certain signs that suggest a more serious issue with the needle positioner. Here’s how to assess the situation:

- Consistency: If the noise is consistent and doesn’t increase, it may be normal. However, if it becomes louder over time, it could indicate wear.

- Functionality: If the needle positioner still works correctly despite the noise, it may just need maintenance. If it starts failing to stop in the correct position, a repair is likely needed.

- Heat and Smell: Excessive heat or a burning smell is a red flag, indicating motor problems that require immediate attention.

Choosing a Quieter Needle Positioner: What to Consider

If you’re looking to buy a new needle positioner and want a quieter option, keep these key considerations in mind:

- Motor Type: Servo motors are generally quieter and more efficient than clutch motors. Opt for a positioner with a high-quality servo motor for reduced noise.

- Build Quality: Look for a well-built, durable positioner made from high-quality materials to ensure smooth, silent operation.

- User Reviews: Read reviews from other users to get an idea of the noise levels and overall performance of the needle positioner.

Conclusion:

Should You Be Concerned About Noise in Needle Positioners?

While some noise is normal in needle positioners, excessive or unusual sounds should not be ignored. By understanding what causes the noise and following proper troubleshooting and maintenance steps, you can reduce it significantly. Choosing a high-quality needle positioner and performing regular upkeep will help keep your machine running smoothly and quietly, ensuring a better sewing experience. If the noise persists despite your efforts, consulting a professional technician can help address deeper issues and prevent potential damage.